PTFE (or polytetrafluoroethylene) is one of the most versatile industrial coatings available today. It offers…

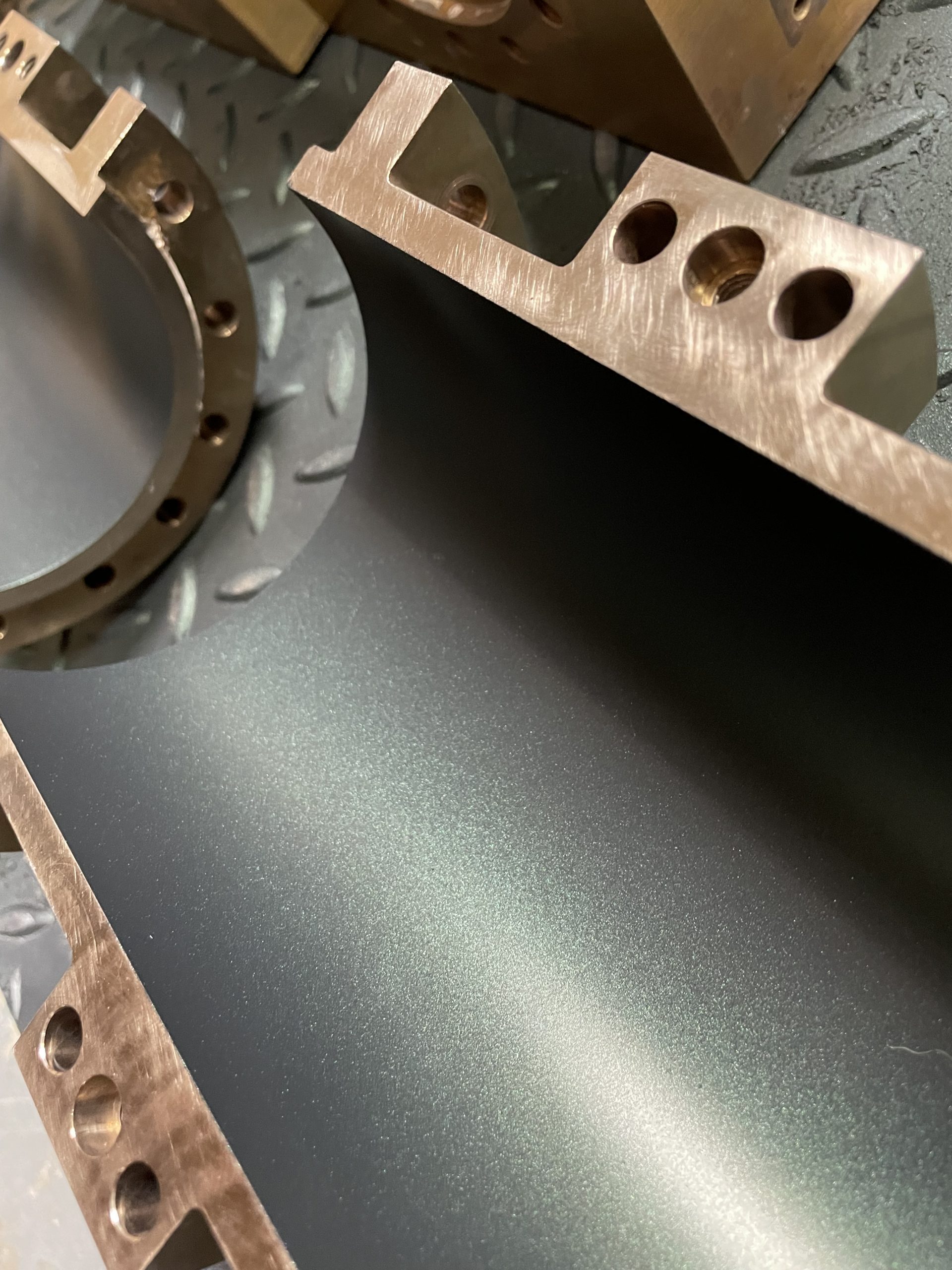

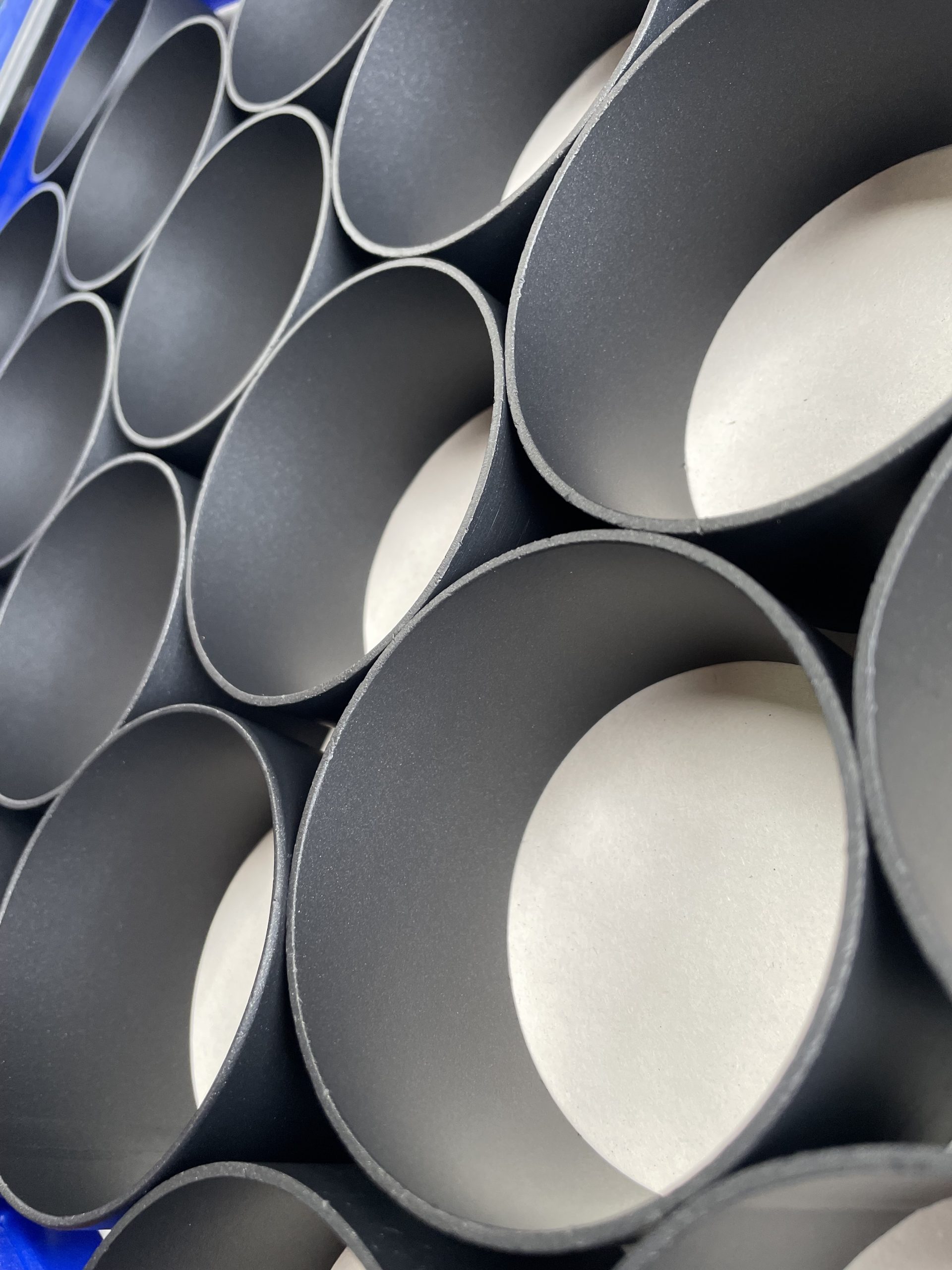

Colour coding implementation (colour range improvement)

Welcome back with our posts after a while! In the meantime we spent a lot of our time on continuous improvement and introduction of new projects to our current and existing customers.

Lately we have received a lot of questions from different markets, about alternative colours to what is currently on the market and we look on it a bit closer. Challenge of different colours is often very demanding as most coating companies are not carrying stock for different colours and as a customer you have to wait long time to get your parts coated back. We would like to face this challenge and help our current and potential customers in reducing this lead time.

We would highly recommend to contact us by bakeries and food manufacturing customers to check on our new range of colours, as it will be beneficial for their production lines. We are sure it will add a value to their production lines as single order line will have all metal equipment in the same colour – simplicity and mistakes elimination in production! 👍

Precision Engineering is a market, where colour does not make a difference in most cases, however lately our inquiries box shows us something else. Our customers are looking for a coating to provide low friction, wear and chemical resistance, corrosion or vibration resistance, but also present their brand as unique on the market.

Blades and knives market is one of the most known areas, where colour does make a difference! Having unique blade on the market means to blades manufacturers they can offer something new to customers expecting highest quality and performance by reducing both friction and heat, extending the life of blades by a factor of three or more (depends on the application).

Contact us for more details with colour you require for your coating application, as naming all colours available would make this post way longer than it neds to! 😊☎️📧